How should I clean my floor ?

Do the Appalachian Flooring products contain volatile organic components (VOC)?

The Appalachian Flooring finishes do not contain any harmful chemical products and do not emit any VOC that are harmful for your health or the environment. Our finishes are exempt from any chemical substances that are harmful to human health. You can use our Appalachian flooring with peace of mind.

My retailer is suggesting that I order a larger amount of flooring than the amount required to cover the area. Why?

Depending on the site and installation type, it is necessary to order between 3% and 5% more flooring to compensate for losses created by cutting planks.

It is also recommended to keep the surplus flooring in case of eventual repairs.

Can I glue the flooring to the substrate ?

Solid hardwood flooring cannot be glued to the substrate. Appalachian Engineered flooring can be glued down. Detailed instructions are found in the Engineered Flooring Installation Guide.

What kind of subfloor do I need to install my Appalachian harwood flooring ?

Installing solid hardwood flooring requires a 5/8” thick plywood subfloor or 3/4″ thick O.S.B. paneling. Engineered flooring can also be installed directly on a concrete slab. We recommend the use of either plywood or flooring grade O.S.B. Please verify the details in the installation guides prior to installing, to fully understand the conditions that must be applied to your construction.

Can I install Appalachian flooring in the basement ?

Solid hardwood flooring must not be installed below grade or in the basement. Appalachian Engineered flooring can be installed below grade and in basements.

Can I switch off my heating or air conditioning when I go away on vacation ?

Unfortunately not. You must maintain relative humidity between 40-50%, and a temperature between 65-75 degrees Fahrenheit at all times.

Do I have to acclimate the flooring before installation ?

Yes it is absolutely necessary to acclimate the flooring for 48 hours prior to installing the flooring. This should be done in the room where the flooring will be installed at a relative humidity of 35‐55% for solid and 35‐70% for engineered.

How long, after installation, do I have to wait before I can walk on the floor ?

If your Appalachian flooring was nailed or stapled down you can walk on it right away after the installation. If your floor has been floated or glued down then you must let the floor cure for the time recommended by the glue manufacturer.

What will happen to my floor if I allow my dogs to run on them ?

Appalachian flooring is very abrasion resistant. However, no varnish or floor is pet-proof. In the Specifications section you can read more about on the hardness of hardwood flooring and the effects of pets on your hardwood flooring.

How do I protect my floors from furniture ?

Place felt pads under the legs of the furniture to protect your flooring from scratches. Additionally, clean these pads regularly to prevent the buildup of sand or other abrasives, which in turn could scratch your floor.

What is the industry standard for looking at defects ?

Inspection should be done from a standing position with normal lighting. Glare, particularly from large windows, magnifies any irregularity in the flooring and should not determine acceptance.

What is a spline or slip joint ?

This is a thin strip glued into grooves cut into the pieces being joined, these are used to fasten two grooves together. They are made with a table saw and dado blade or with a router and straight bit. In some cases, such as bay window or closet areas, it may be necessary to reverse directions or back-fill an area. In that case you will be installing a groove against a groove and will need to use a spline. Glue the spline into the groove, this will transform the groove into a tongue. You can then continue installing as usual.

Why is my floor cupping ?

Cupping or “Washboard” is when: across the width of one piece of the flooring material, the edges are high, the center is lower. This is not a manufaturing defect, this is caused by an imblance of humidity. The material was manufactured flat and was flat when installed but appears wavy or cupped after. The causes can be excessive airborne humidity (Relative Humidity) – dehumidify air space or (lack of during heating season humidify air space); wet basement – ventilate, dehumidify; crawlspace groundcover/vents, add exhaust fan on timer; lot topography – french drain to remove; rain handling provisions – correct to drain away from house; excessive lawn/garden moisture – reduce/waterproof foundation; leaks plumbing, roof, doors – fix; don’t hose patio; maintenance; correct capillary through slab – install barrier, french drain, drain tiles. In kitchens, the dishwasher and ice maker are notorious leakers. To help you can purchase a dehumidifier to place in your home to bring the flooring within 40-60% relative humidity (as specifed in warranty) in addition most electronic stores have a hygrometer to mointor the levels of the humidity.

What is a microbevel ?

Angled edges milled around the top edges of prefinished floor boards are called a microbevel or v-joint. The higher end flooring has this present on all four sides to accentuate the look of the individual pieces of flooring and to add depth to the flooring. Some market this as a “kissed edge”, “micro-v”. Square edges are used in unfinished applications.

How do I clean up cured urethane adhesive after installation ?

First clean up adhesive as soon as possible when in wet state.

We recommend the use of Bostik best adhesive cleaner or Sika wipes. If adhesive cannot be removed when wet, find a small test area first or a discarded piece to test prior to removing adhesive on the floor.

- Apply a liquid urethane adhesive remover to the area making sure to cover an area slightly larger than the adhesive spot itself. Allow the remover to soak for at least an hour to fully penetrate and soften the dried adhesive.

- When softened use a 1-2 inch plastic putty knife to break the adhesive free from the wood floor. Care should be taken not to scratch or mar the finish of the floor.

- Use a melamine pad ( like a Mr. clean Magic Eraser) to remove any remaining adhesive residue or haze from the floor finish by saturating the pads with the liquid remover and scrubbing the surface. It is important to take care not to scrub a matte finish too hard and accientally polishing it to a gloss.

- Many of the removers leave an oily residue after removing the adhesives. These should be cleaned along with the entire floor with Bona cleaner.

Will my floor have color variations in it ?

Yes. Wood is a natural material with variations from board to board. Each plank will accept stain differently. Lighter stain colors don’t hide or mask natural characteristics as much as darker colors. Even with a stain color there is some variation of color due to the woods variation from board to board.

What is the difference between solid flooring and engineered and laminate ?

Solid wood floors are made with only one piece of wood generally 3/4″ thick. The planks are available in 2.25”, 3.25” and 4.25”. The length of the planks can vary between 9” and 72″ depending on the grade and the species.

Solid wood floors can react to the environment in which they are placed, especially if a humidifer and dehumidier are not used to maintain the humidity between 40-60% .

In the winter heating months, the moisture content of the wood reduces causing the floor to contract or leave small gaps between each board. In the summer months when humidity enters the wood, it will cause the wood to expand and if there is too much moisture, it can cause the floor to cup. It can be installed on and above grade.

Solid wood floors are most commonly installed by nailing down to a wood subfloor.

Engineered hardwood floors refer to products that have a solid hardwood layer with a plywood core. At Appalachian Flooring, our plywood core is made with Baltic Birch wood. The most common engineered hardwood flooring widths are 4”, 5”, 6”and 7″ and thickness are 1/2”, 11.4mm and 18.4mm. Engineered wood floors plywood cores offer maximum stability. These floors will be less affected by moisture than solid wood floors.

Engineered wood floors can be installed on and above grade, in basements, on radiant-heated floors and on concrete slabs, places where traditional solid hardwood floors are unsuitable. Engineered wood floors have several options of installing; nail down, staple down, glue down, and some can even be floated.

Engineered wood floors are made completely from wood unlike Laminate. Laminate-core of product is typically made of High Density Fiber (HDF). The top layer is a photographic layer that should appear identical to the product it replicates, be it wood, vinyl, tile, etc.

Is it normal that my flooring has dents ?

Yes, wood dents. CAUSE: High heels. Dropped heavy objects, metal tips on furniture legs. Unprotected rolling of heavy appliances such as refrigerators or freezers, or children toys.

CURE: Remove high heels or maintain proper heel-tip protectors. Provide large felt or rubber protectors under heavy furniture legs. Roll heavy casters over plywood protection only. You can read more information on this in the specifications section of the web page.

Nail, glue or float ?

Nail Down Hardwood Floors A hardwood floor can only be stapled or nailed when it is being applied over a plywood or an O.S.B. subfloor. A naildown floor cannot be nailed directly to a concrete subfloor. Stapling is an accepted method but is not preferred as it may lead to noisier floors. Nail down hardwood floors should not be used in homes where the climate is not controlled year round, such as summer homes, because extreme changes in temperature and humidity will cause a 3/4″ naildown floor to shrink and expand.

Glue Down Hardwood Floors A glue down floor can be applied over almost any subfloor. Glue down floors can be refinished. Typically solid flooring is not glued down. Floating Floors Engineered flooring can be floated by gluing the tongue and groove together. These floors cannot be refinished. Solid flooring is not floated.

What is the difference between sawn and rotary cut lamella on the top layer of my engineered flooring ?

Dry Sawn lamella – The lumber is cut lengthwise. With this method, it is possible to sand you engineered flooring. At Appalachian Flooring, we use dry sawn lamella for our engineered hardwood flooring.

Rotary cut veneer – The veneer log is rotated against a stationary knife to produce a sheet of wood. This method is the most economical method of producing veneer. Rotary cut veneer gives more distinctive and varied grain patterns. Dry Sawn is considered superior to rotary peeled lamellas.

What are the differences between job site finish and prefinished flooring ?

Factory cured factory applied urethane finishes eliminate numerous problems that are prevalent with job site applied finishes.

Foreign particles that fall into the finish while it is curing and applicator marks being two common issues.

After application, a site finished floor scuffs easily and will have to refinished sooner. Prefinishes floors tend to last much longer and scuff less easily.

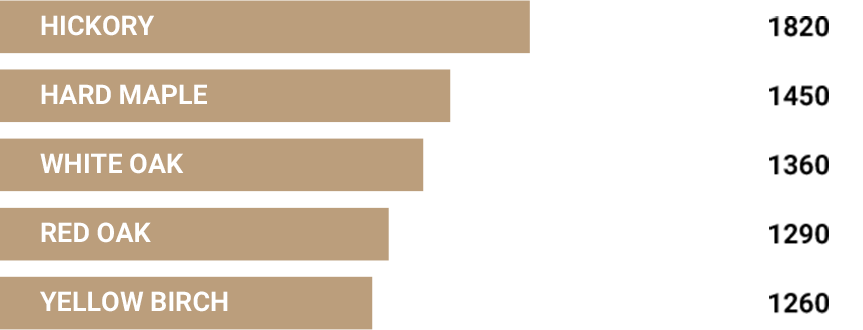

What is the Janka hardness scale ?

The Janka test measures the force required to embed a 0.444 inch (11.28 mm) steel ball into the wood by half its diameter. The result of this test is one of the best measures of the ability of a wood species to resist wear and dents. This is why there are several important variables to consider when you are planning to buy hardwood floor. Color and look are important, but you must also consider wood grain, stability and hardness.