The grade of a wood floor represents its appearance. since each plank is unique, we have classified them according to their variations in color and the character marks that are naturally present in the wood flooring. the choice of grade is, in fact, a matter of appearance.

For the most accurate information about appalachian flooring’s grading system, please refer to our grade specifications document.

AVAILABLE IN 2 PLATFORMS: ENGINEERED AND SOLID WOOD

AVAILABLE IN 2 PLATFORMS: ENGINEERED AND SOLID WOOD

AVAILABLE IN 2 PLATFORMS: ENGINEERED AND SOLID WOOD

AVAILABLE IN 1 PLATFORM: ENGINEERED WOOD

AVAILABLE IN 2 PLATFORMS: ENGINEERED AND SOLID WOOD

Available in 2 platforms: Engineered and Solid Wood

AVAILABLE IN 1 PLATFORM: SOLID WOOD

AVAILABLE IN 1 PLATFORM: SOLID WOOD

AVAILABLE IN 1 PLATFORM: ENGINEERED WOOD

AVAILABLE IN 1 PLATFORM: ENGINEERED WOOD

AVAILABLE IN 1 PLATFORM: SOLID WOOD

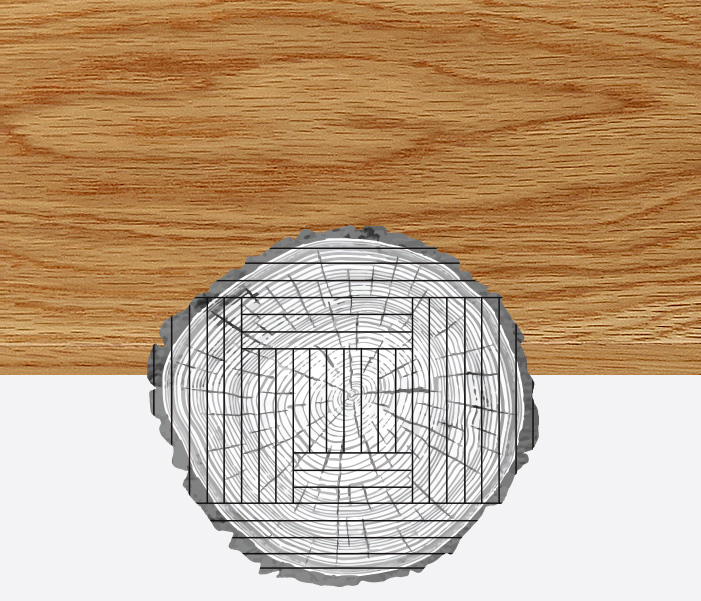

Plain sawing or flat sawing is the usual method employed in transforming logs into lumber destined for the production of hardwood floors. The wood cut yields the distinctive arch pattern in the grain.

Live sawn boards are created by cutting the log straight through with minimal waste. The resulting boards display the full range of the log’s natural characteristics with a unique mix of quarter sawn, rift sawn, and plain sawn. Live sawn has more character than most gradings.